Manufacturing

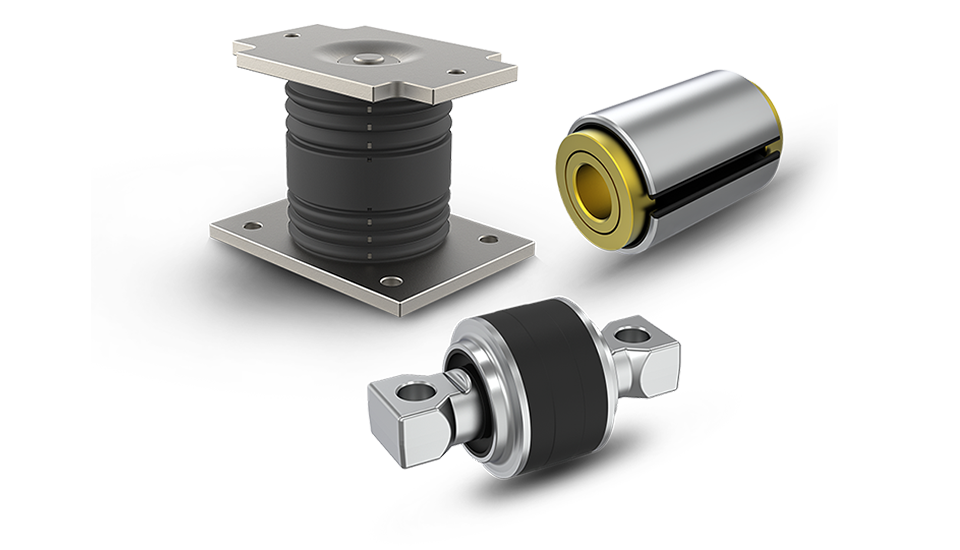

From Specifications to Perfect NVH Solutions. Integrated Strength of ACCURUB.

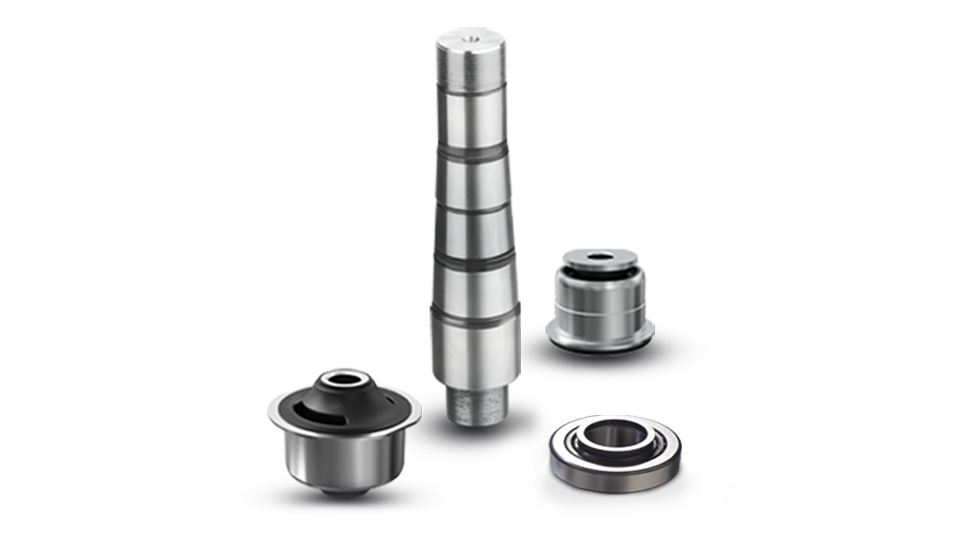

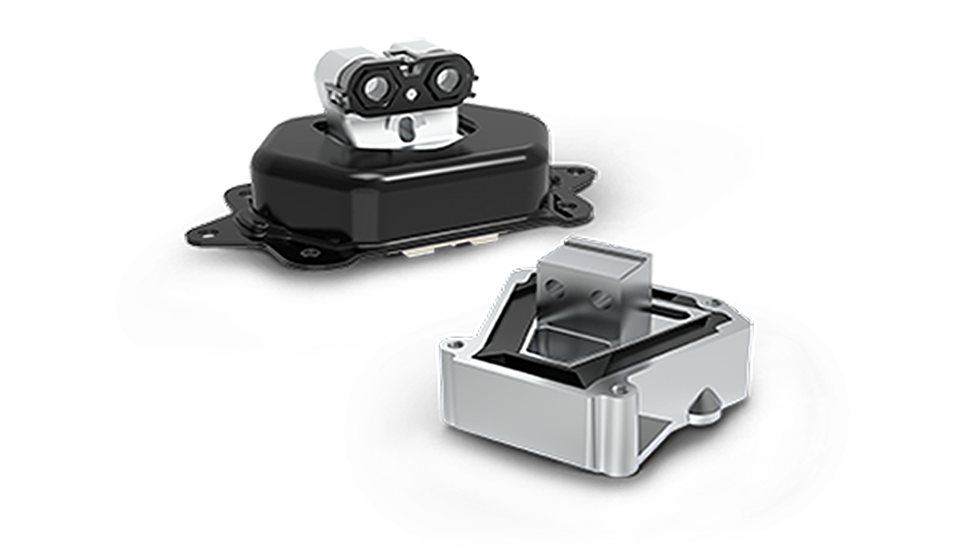

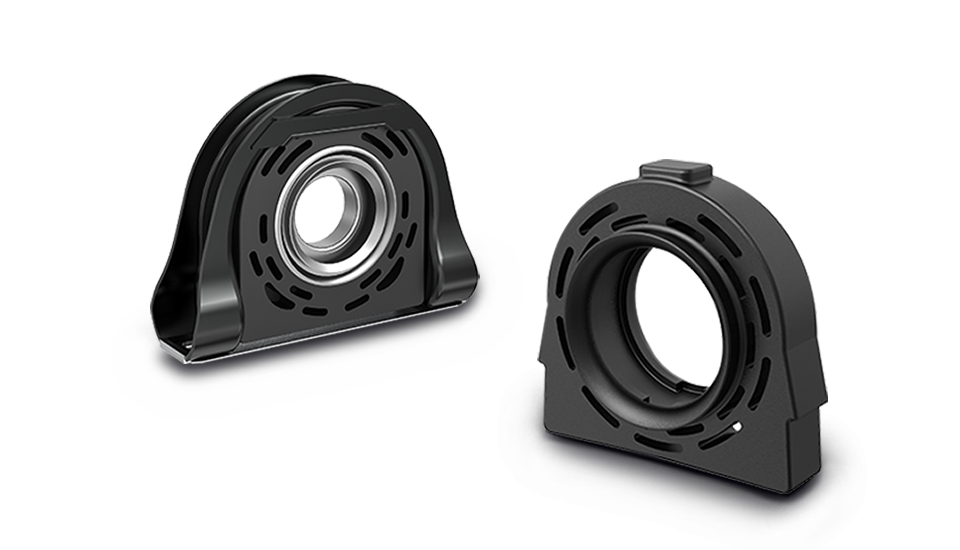

Machined Component

Division

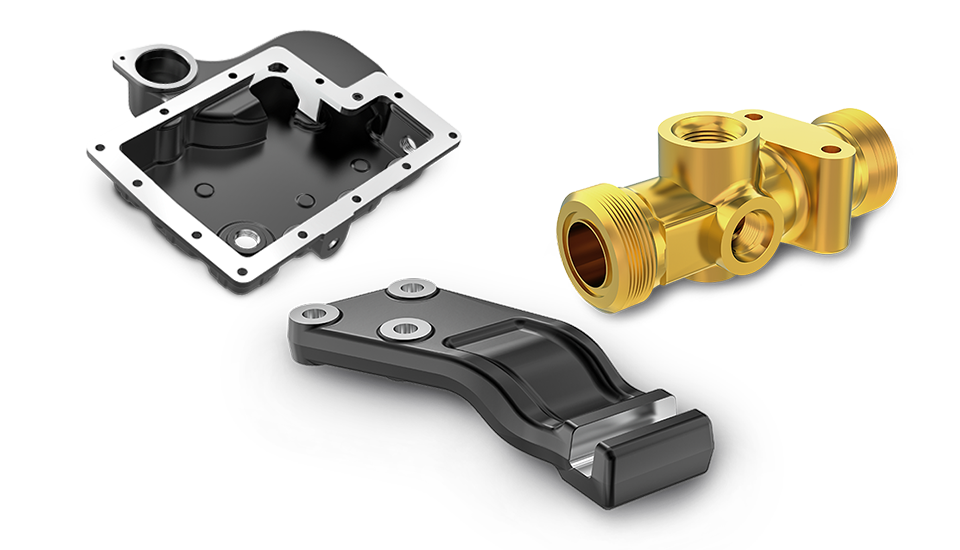

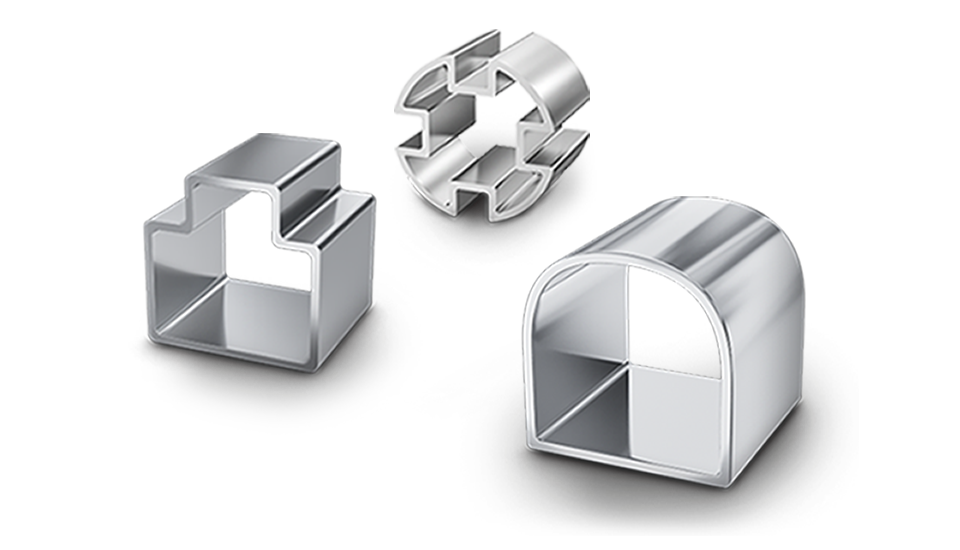

We Convert and Deliver Around 6,500 MT/Annum of Tubular, Casting, and Forging Components.

Manufacturing quality NVH components demands outstanding manufacturing processes and innovative solutions. At Accurub, our 4,000 m² spread precision-machined component division hosts state-of-the-art CNC, VMC, and forged casting machining, HMC machinery with SOCO tube, bar cutting, and 3-axis CNC tube bending machines.

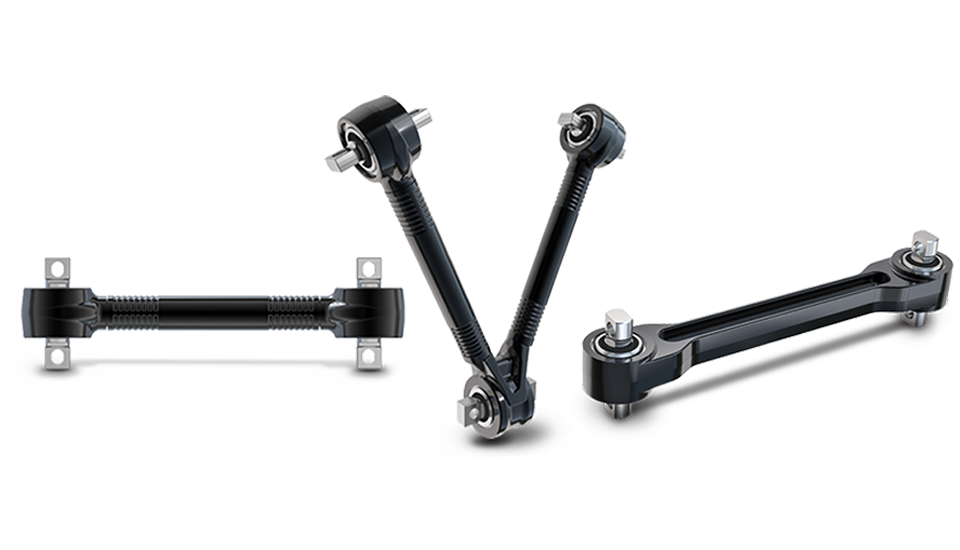

The Accurate Production of Components

Accuracy and consistency of machined parts and components significantly impact a vehicle’s performance in noise, vibration, or harshness reduction. At Accurub, our focus is on manufacturing components with reduced errors, increased efficiencies, and contributions to the optimal functioning of the final product. Consistency and quality of machined parts are achieved through automation, which also helps in reducing production costs.

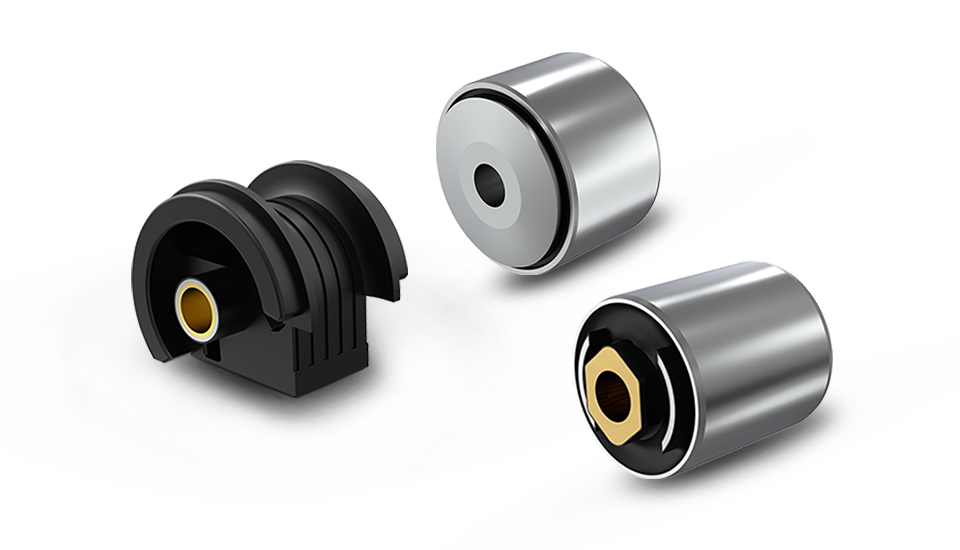

Efficiency and Consistency

Our manufacturing process framework is based on our standardized work processes, lean manufacturing, and the delegation of authority. Special care and attention are given to eliminating waste in production and utilizing materials more efficiently. At Accurub’s Component division, production processes are planned and managed via the ERP system.