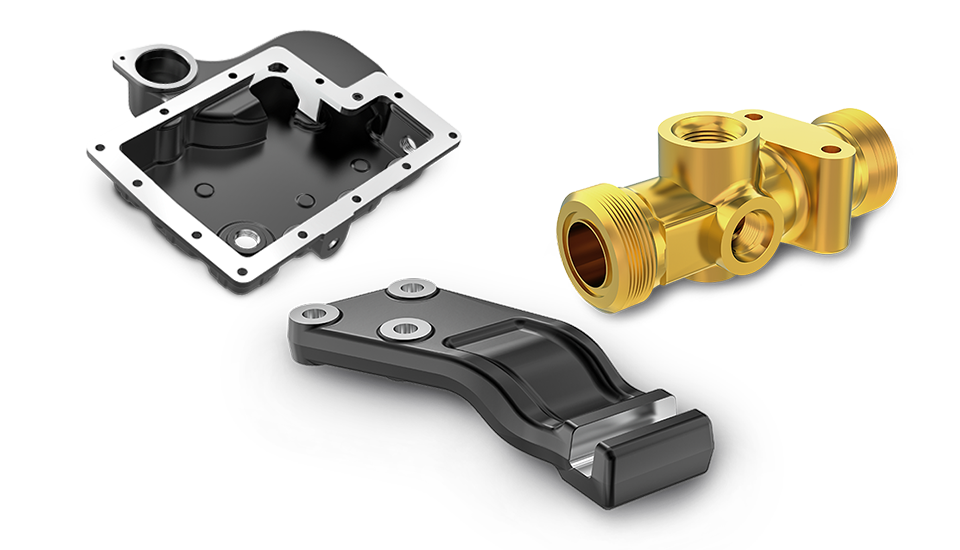

Manufacturing

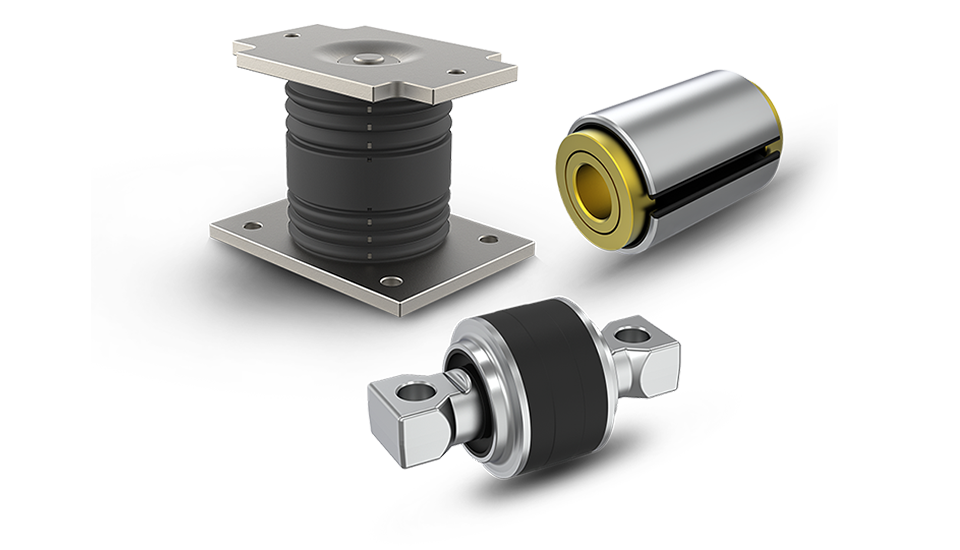

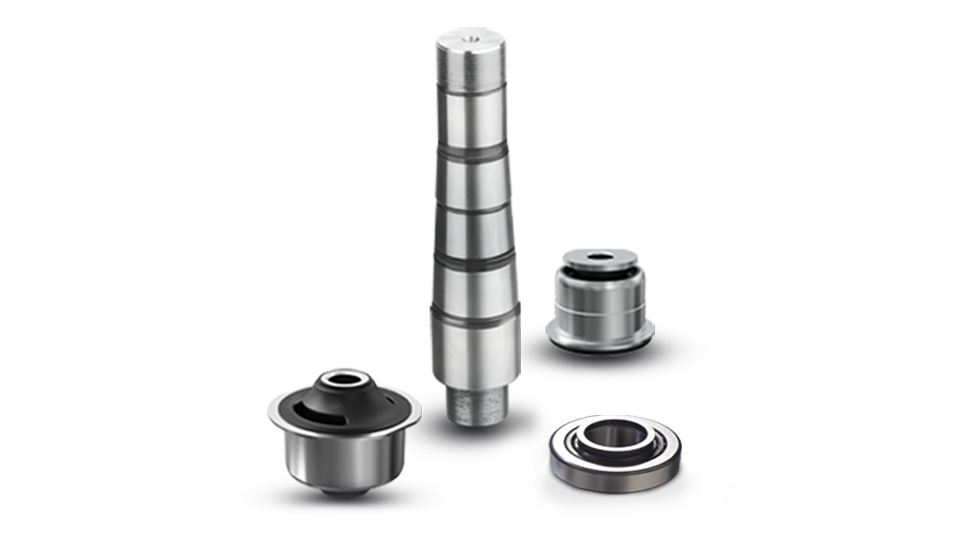

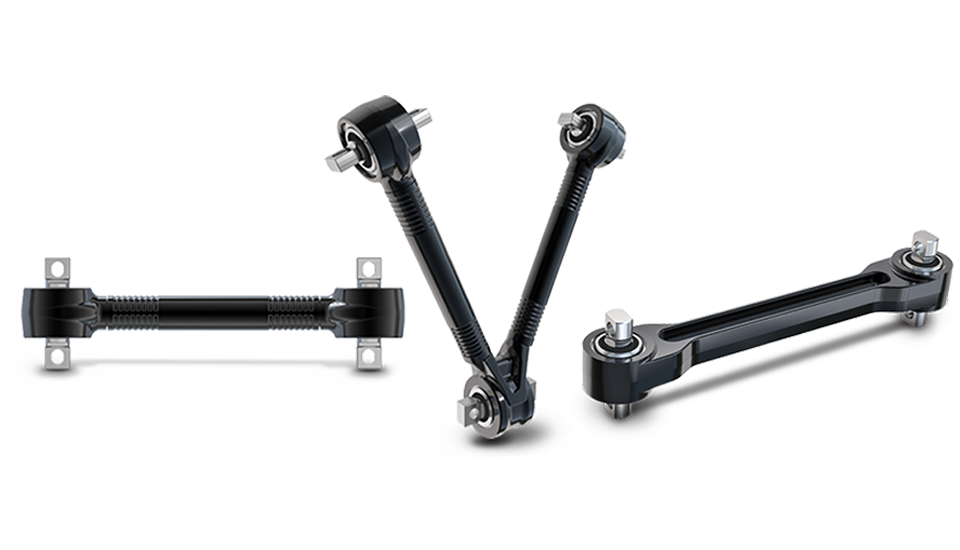

From Specifications to Perfect NVH Solutions. Integrated Strength of ACCURUB.

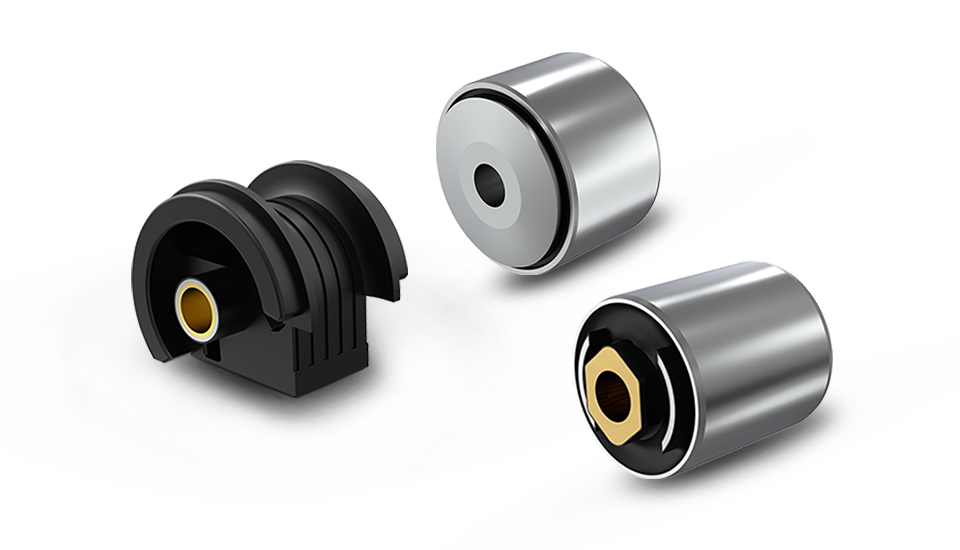

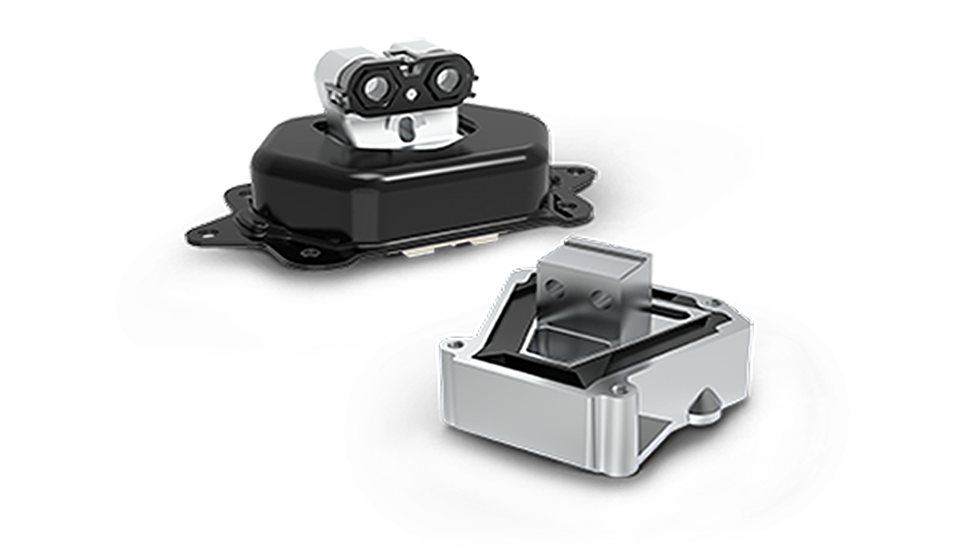

Polymer and Compounding Division

Our 2,800 m2 Polymer and Compounding Facility Has Stringent Enclosed Compound Mixture Technology and Process.

Our every compound recipe is uniquely prepared and treated with an engineered chemical combination of natural or synthetic rubber base supplemented with chemicals to restructure the base characteristics to achieve the desired outcome. These well-analyzed proprietary formulations can withstand the highest thermal loads, offer optimal temperature resistance and durability, ensuring high performance and NVH optimization.

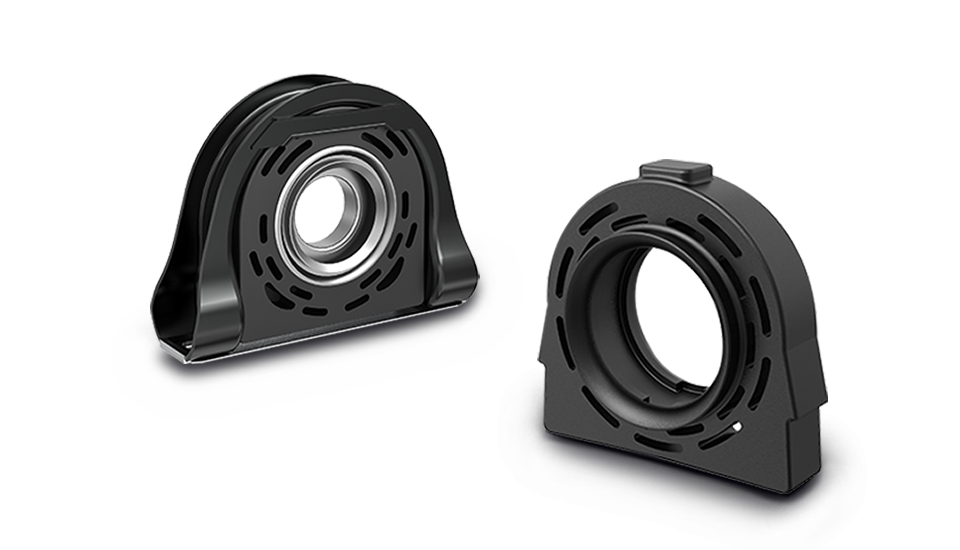

Controlled Time, Temperature and Pressure

To achieve the highest consistent compound results and control on time, temperature, and pressure, we have invested in enclosed temperature-controlled automated recipe mixing technology for chemicals, oil, and carbon. The facility is also equipped with stringently controlled storage for raw and finished goods, with a management system along with an automatic weighing system, with an installed capacity of 25 tons per day.

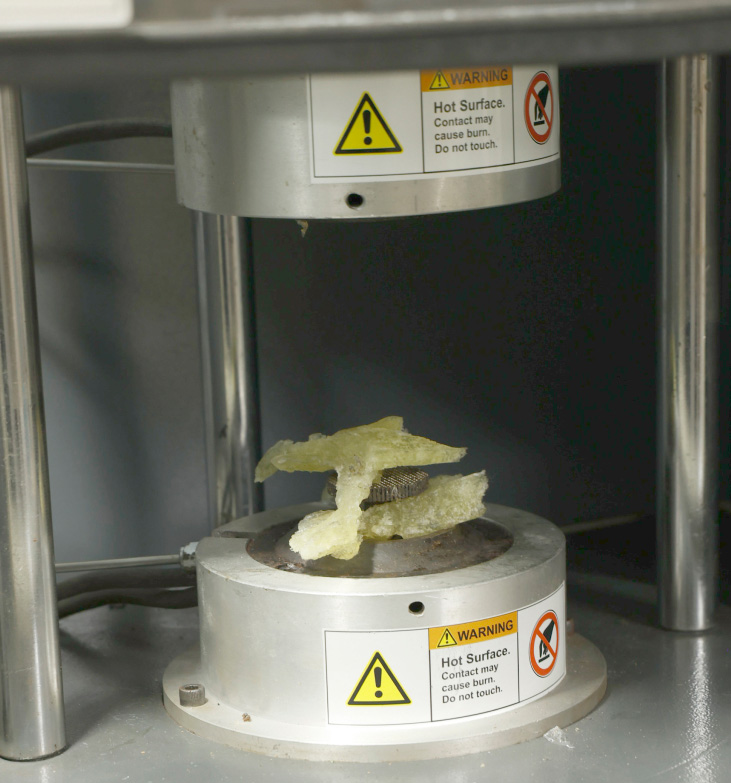

Ensuring Validated and Tested Rubber Compunds

These customised rubber compounds are vigorously tested and validated at our in-house testing before consuming for productions ensuring sustained quality at all times. Each batch of rubber sheets is backed by complete end to end traceability solutions controlled by ERP systems.