Manufacturing

From Specifications to Perfect NVH Solutions. Integrated Strength of ACCURUB.

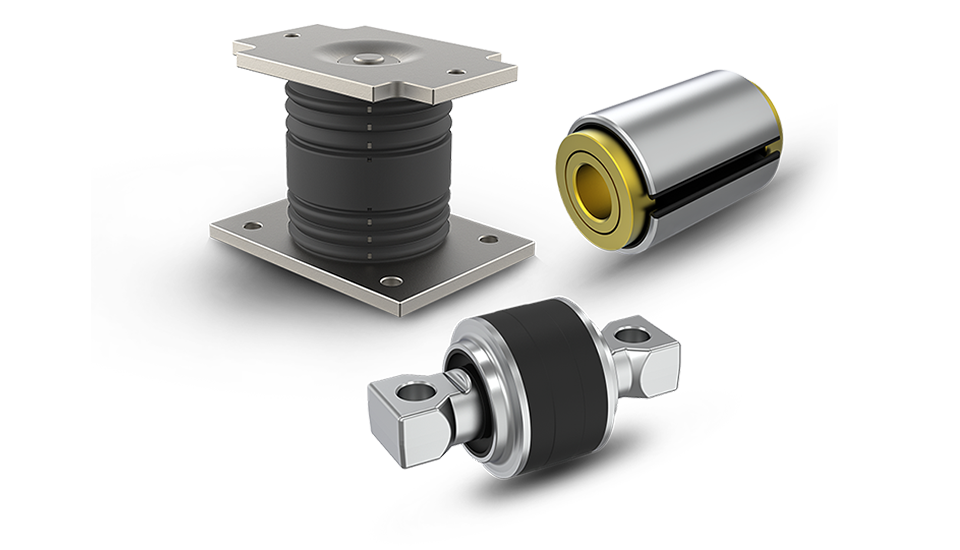

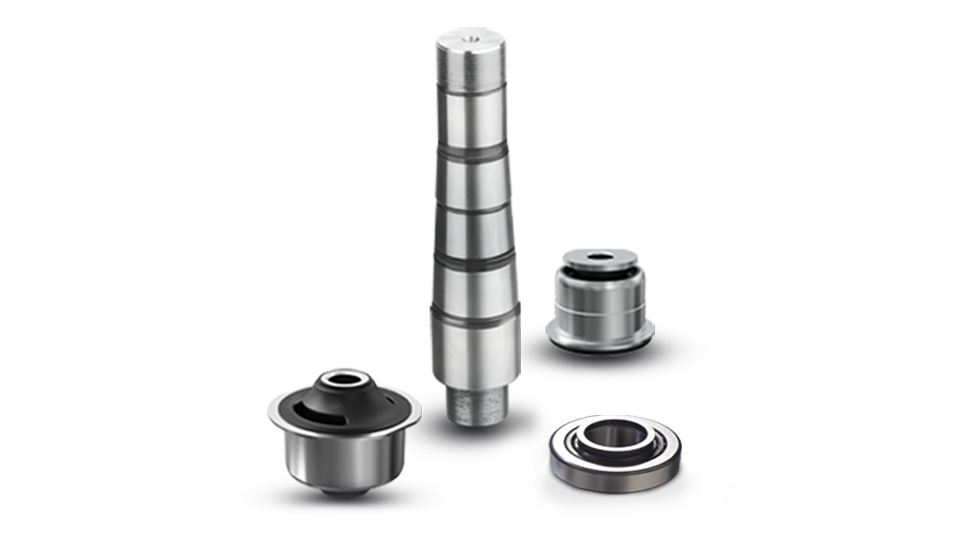

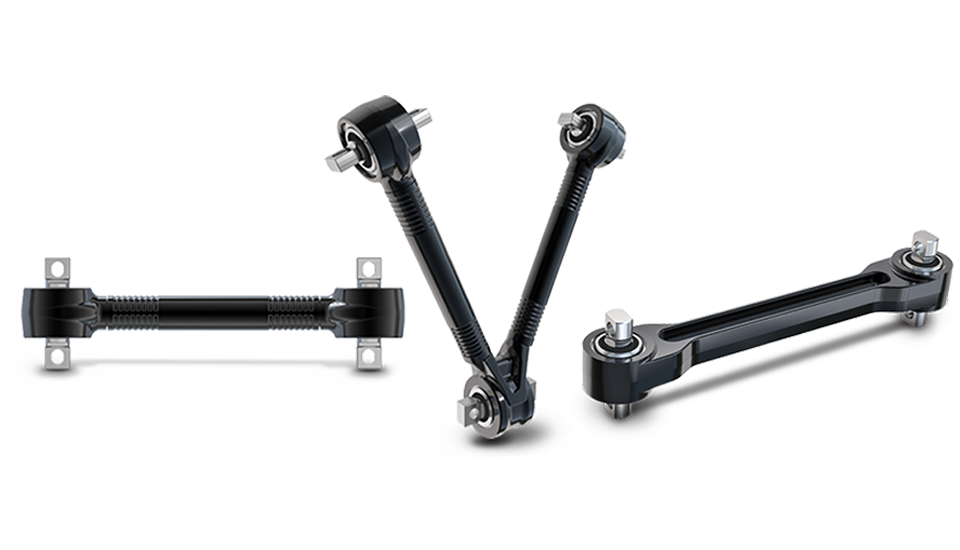

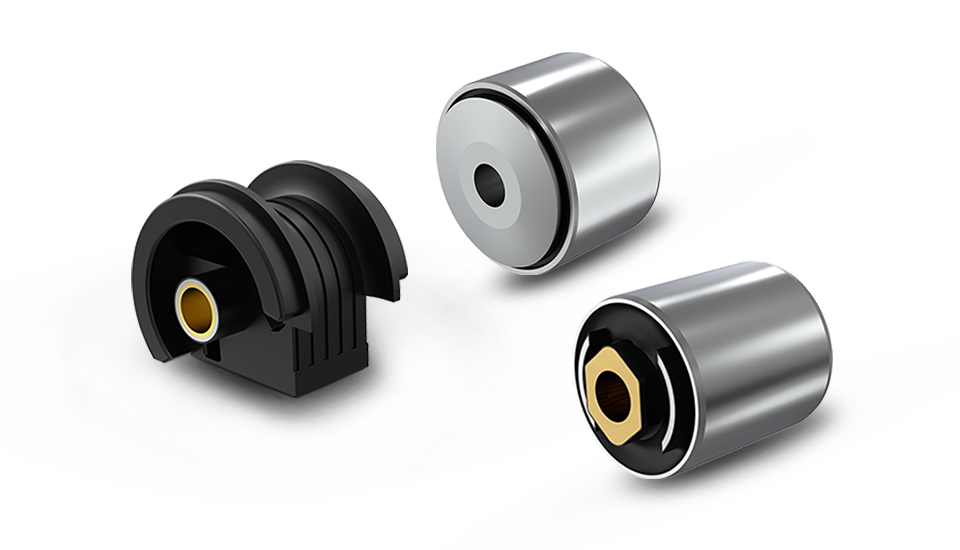

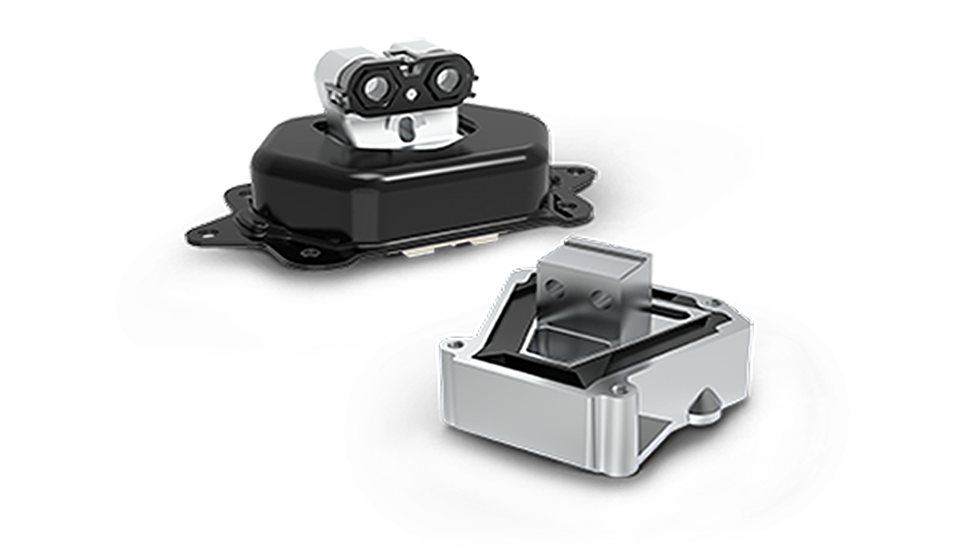

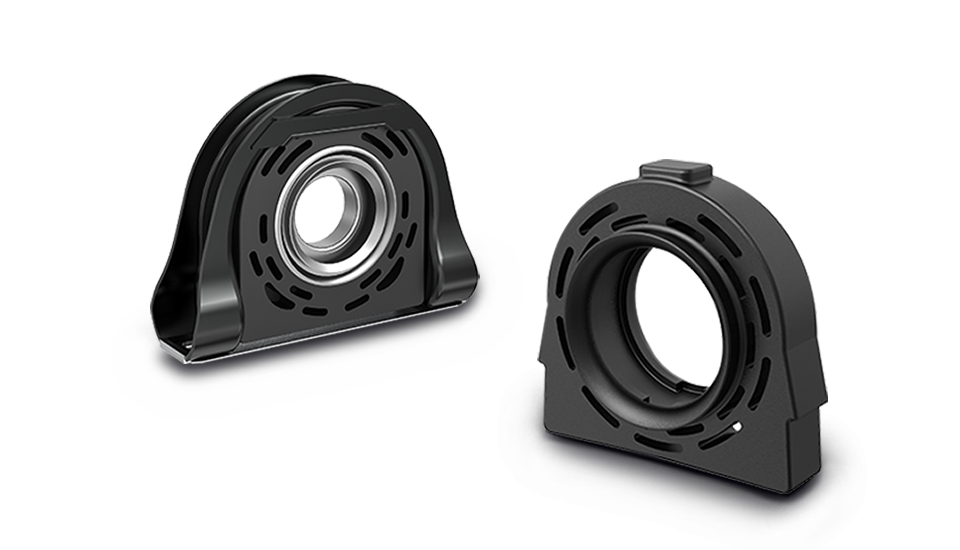

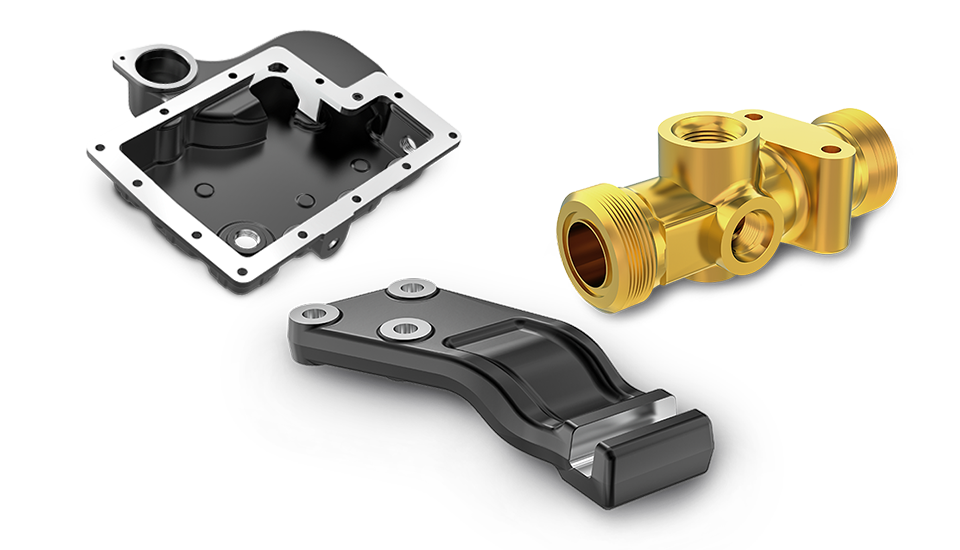

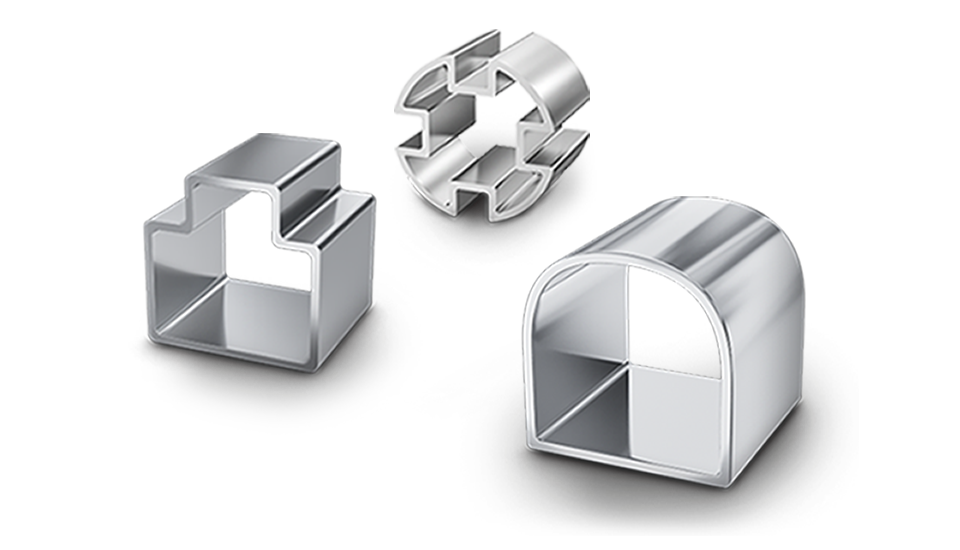

Rubber to Metal Division

From 100 Tons to 350 Tons, Producing Around 15 Million Parts per Annum.

Our Vulcanization division has the latest Klockener Desma injection presses with capacities ranging from 100 to 350 tons, producing around 15 million parts per annum. The facility also houses silicon compound injection molding machines, transfer and molding presses with capacities ranging from 50 to 250 tons, and compression molding presses with a capacity of 350 tons.

High Tech

Process Control

This high-tech process control automated molding facility ensures the perfect combination of temperature, pressure, and time, resulting in the OEM-demanded required NVH performance and characteristics.

Controlled

Environment Zone

The facility has a controlled environment zone for rubber batch storage, ensuring the retention of adequate properties in rubber batches coming from the Polymer division, thus ensuring durable on-field performance.