Manufacturing

From Specifications to Perfect NVH Solutions. Integrated Strength of ACCURUB.

Tooling & Moulds Manufacturing Division

Accurub’s Precision Tooling Division Harmoniously Transforms Component Designs into Tangible Tooling.

Our advanced tool-making department is well-equipped with cutting-edge facilities, including CNC machines, VMC machines, and EDM Wirecut machines that craft tooling components with utmost accuracy. Quality control is ensured through metrology and inspection equipment.

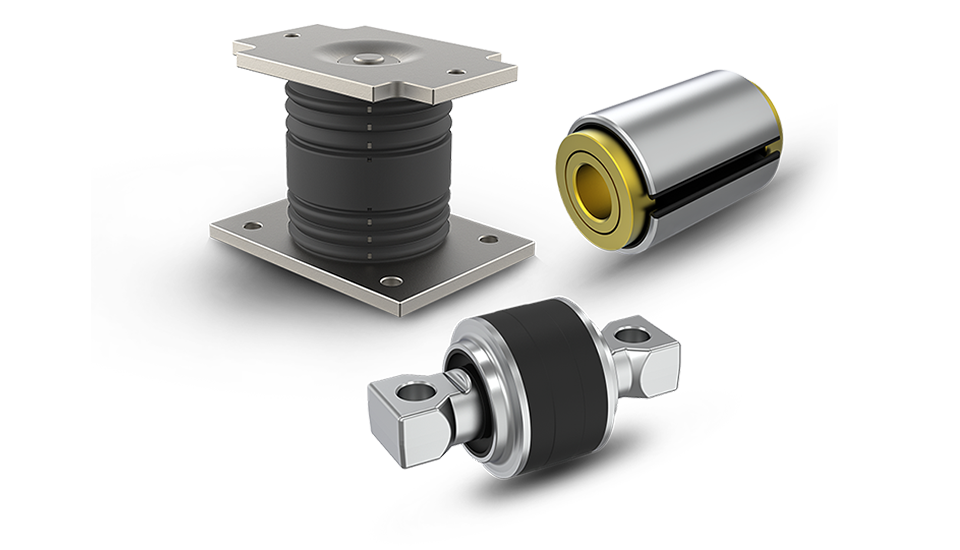

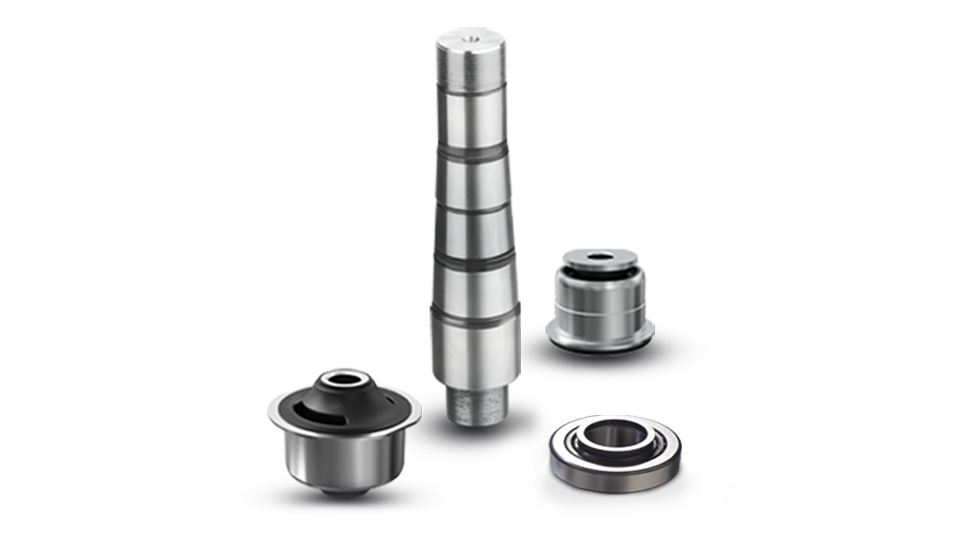

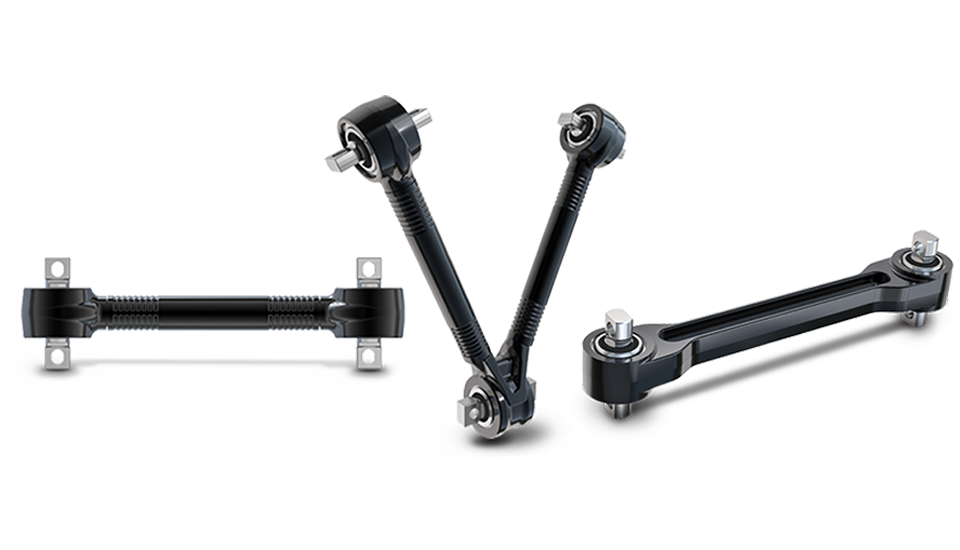

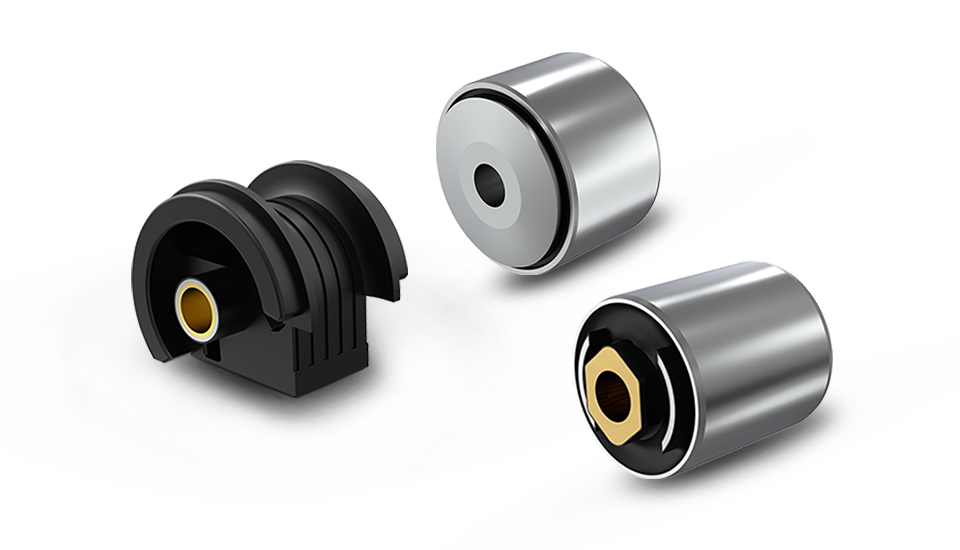

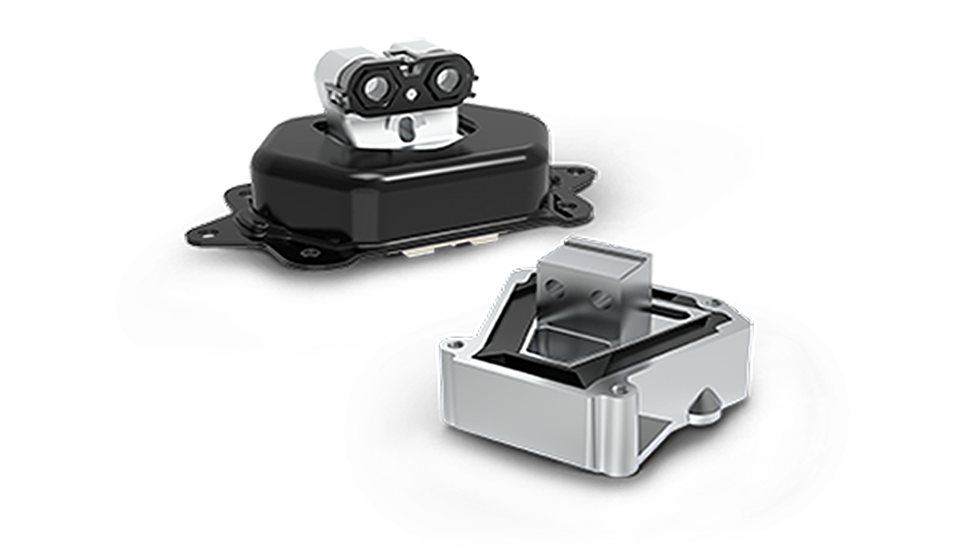

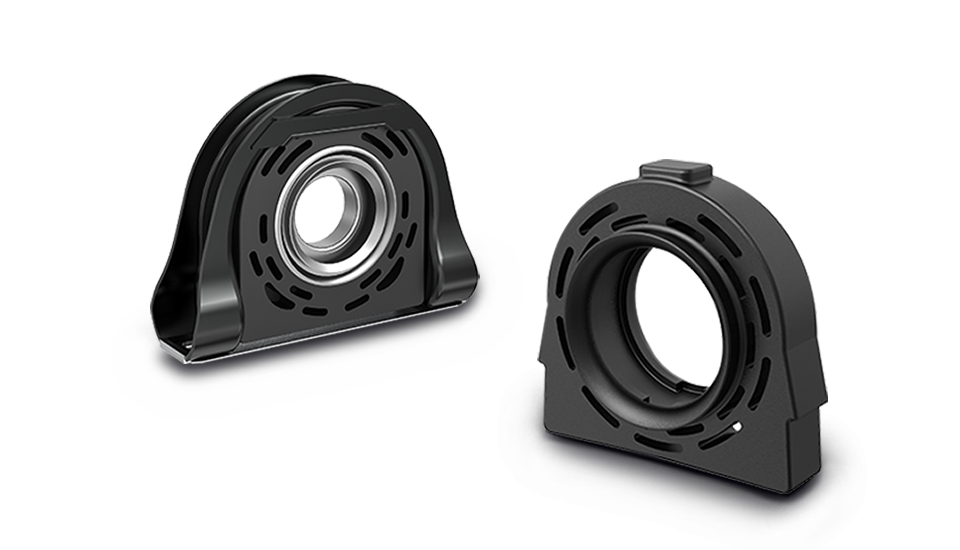

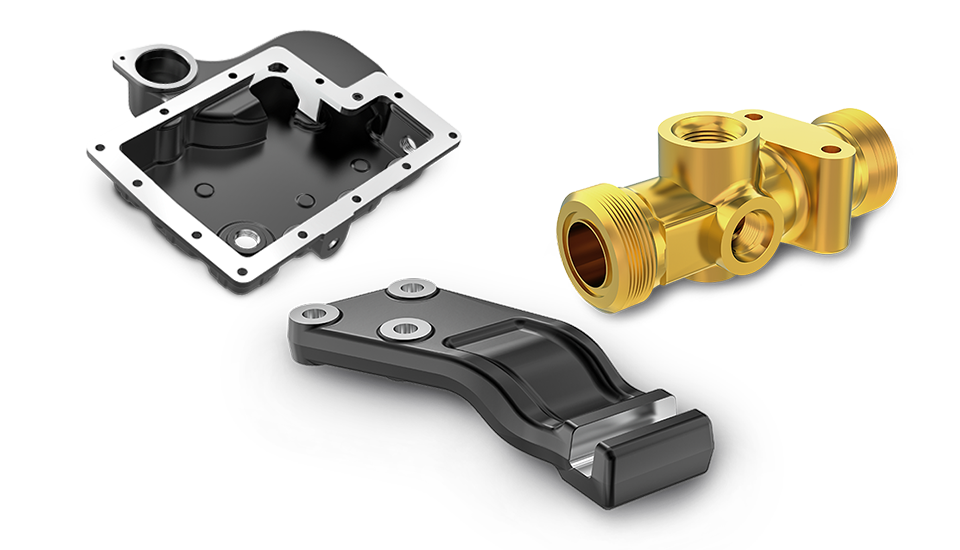

Driving high-performance rubber-to-metal auto component creation

Our in-house tooling capability offers you swift responses and enhanced availability. Whether it’s new component development or refining existing designs, our internal prowess slashes lead times, ensuring swift product development and availability. With Accurub, you gain an edge in time-sensitive operations. Additionally, by minimizing reliance on external suppliers, we harmonize precision with cost efficiency, ensuring competitive pricing without compromising quality.

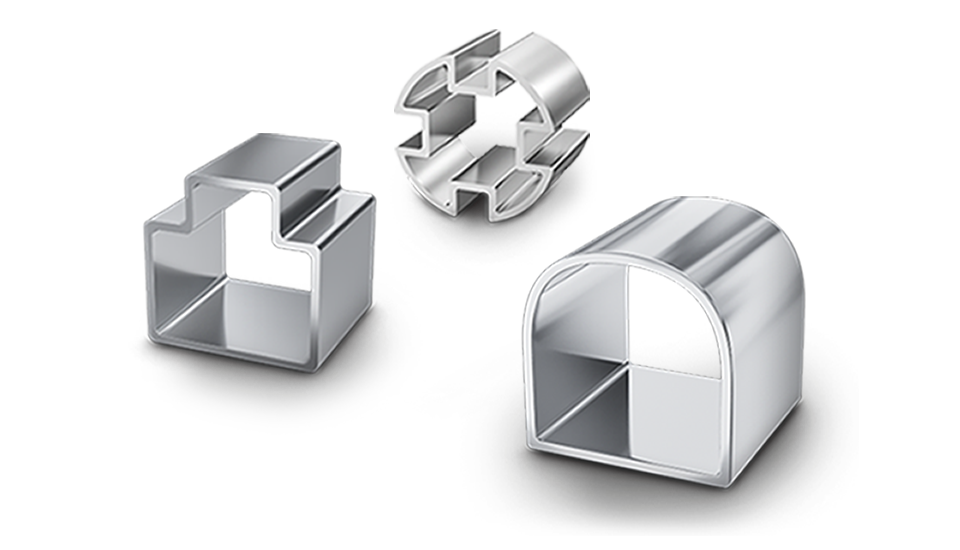

Engineering Precision within Mold Tooling

Accurub’s tooling division showcases meticulous expertise, honing precision. Our approach to rubber injection mold tooling covers essential factors like precise mold design, material compatibility, controlled molding conditions, and durable tooling components. Our engineers’ extensive grasp of machining, material science, and troubleshooting underlines our unwavering commitment to precision and consistent quality.