Our Aim

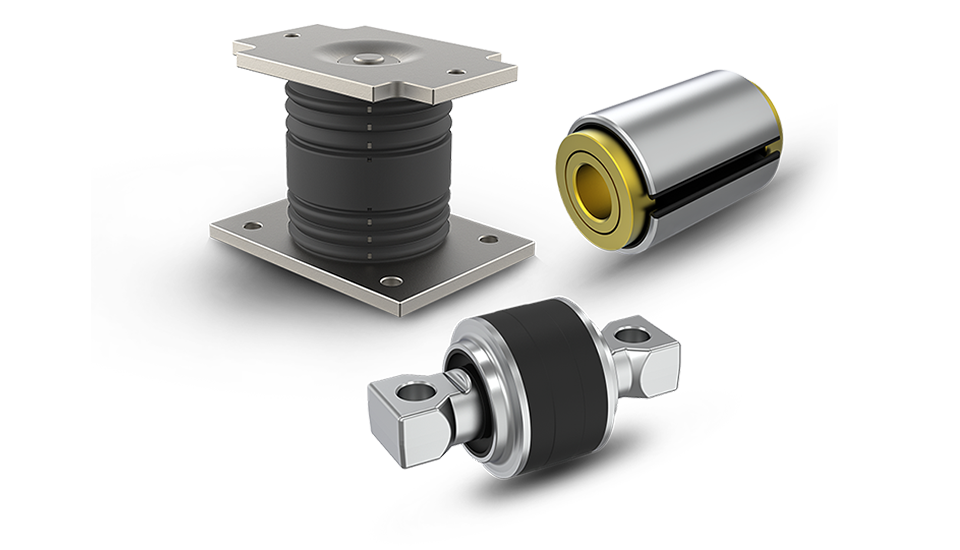

Each Accurub Component should stand for its promise of long enduring journey and comfort.

Tech

Department

01

Adopting technology support and advancement as a means to achieve our promise to our customers.

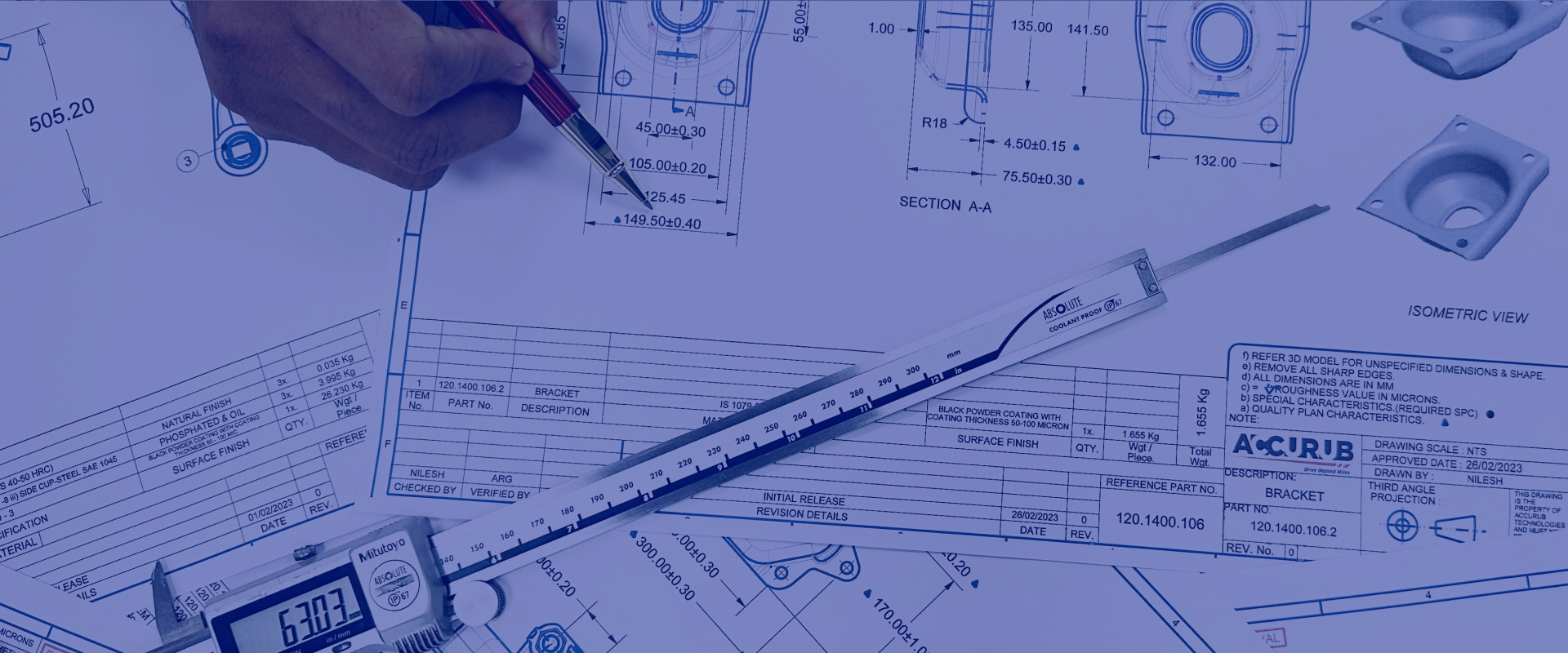

Accurub believes in being with changing time. To ensure the smooth serial production and beyond, we follow a holistic technology approach while

collaborating within different departments and production units across our manufacturing line.

Our highly skilled technicians use latest technology tools, machinery and practises at every stage of the planning, development and production process.

With these Tech Departments, Accrub is constantly in pursuit of new products, processes, materials,

and methods.

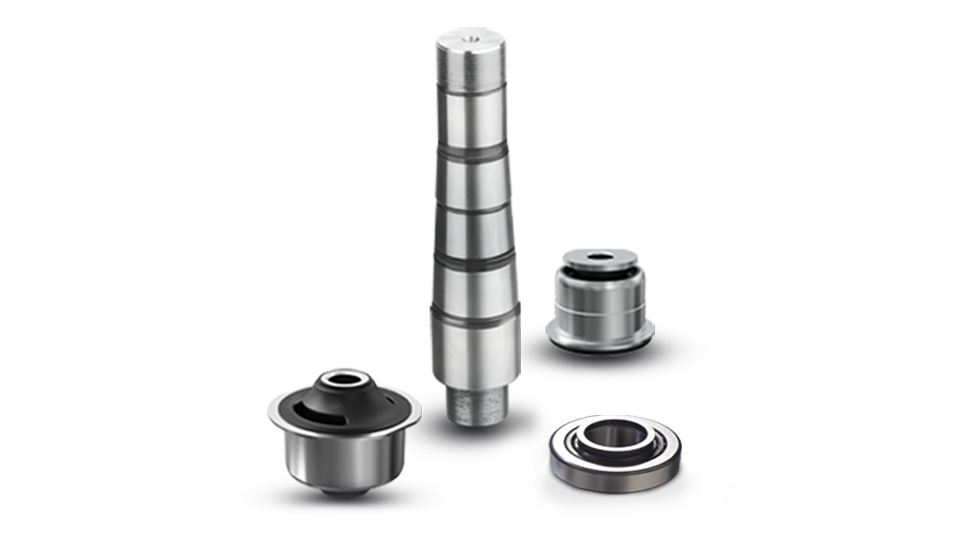

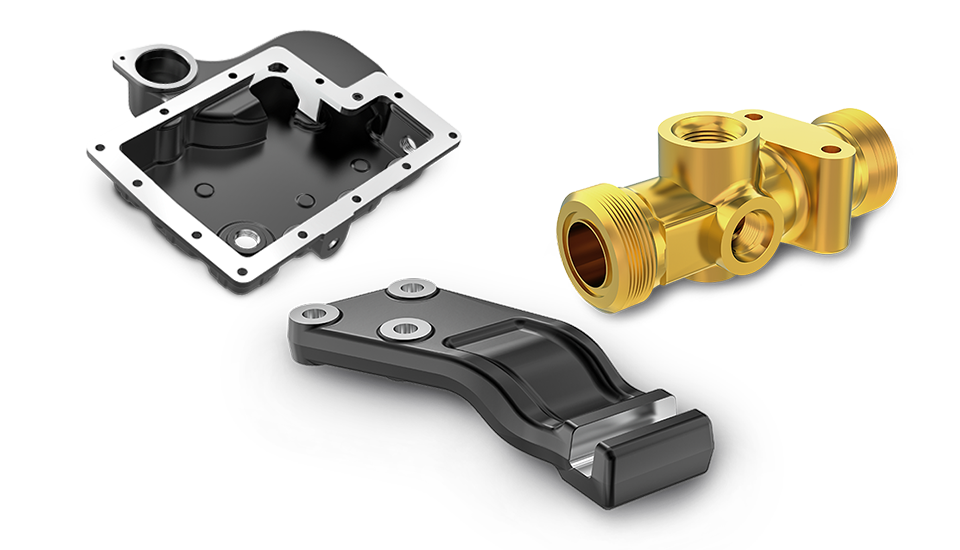

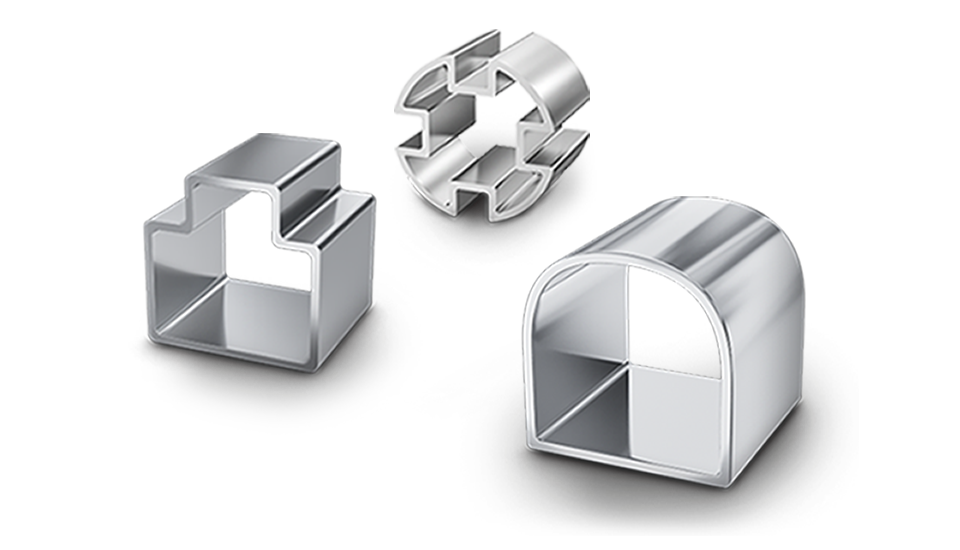

Laboratory & Material Technologies

Different grades and types of materials like Rubber, Plastic and metal alloys are studied, developed and tested at our Material Technologies division to ensure opitimised efficacy of serial productions as and when required.

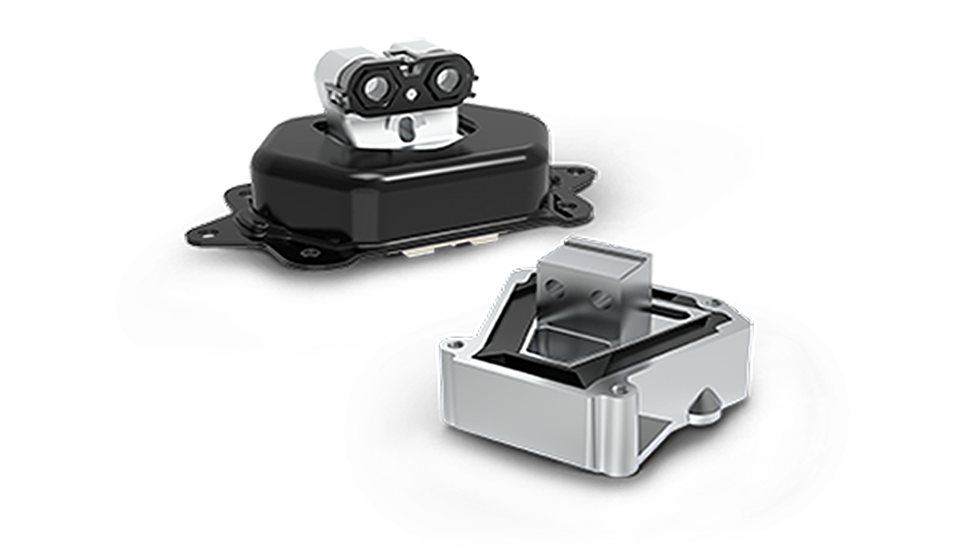

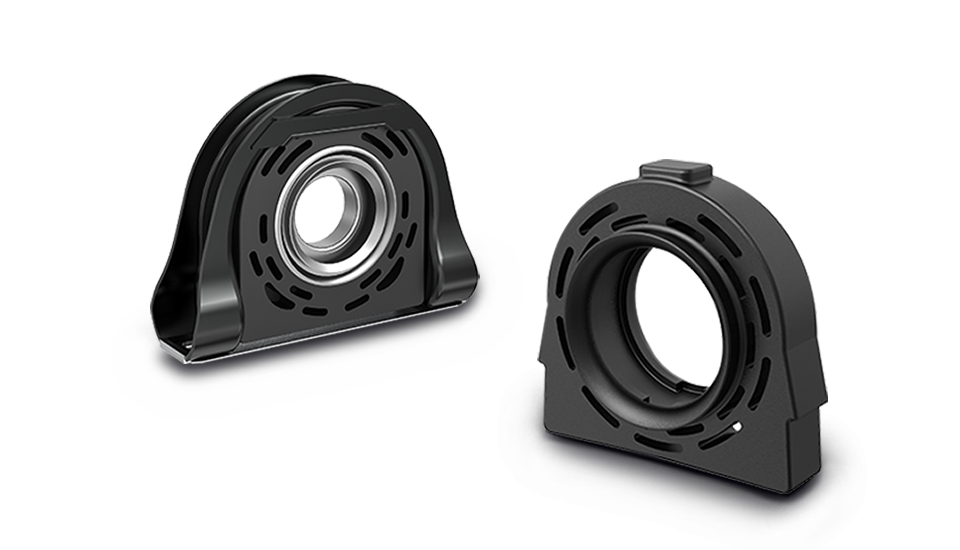

Product Technologies

Product Technologies division, our technicians are assigned and specialized according to strategic product groups, while developing on demand specific products.

In house customised methodologies and development solutions for the critical engineering challenges is what our Engineering Technology team task at.

Engineering

Technologies

Manufacturing

Information System

Our end to end raw material to finished goods process is governed by Manufacturing Information Systems (MIS). The system generated real time data records and data enables optimization of the process, improves efficiency and potentially reducing errors and downtime.

A different

stringent tests

02

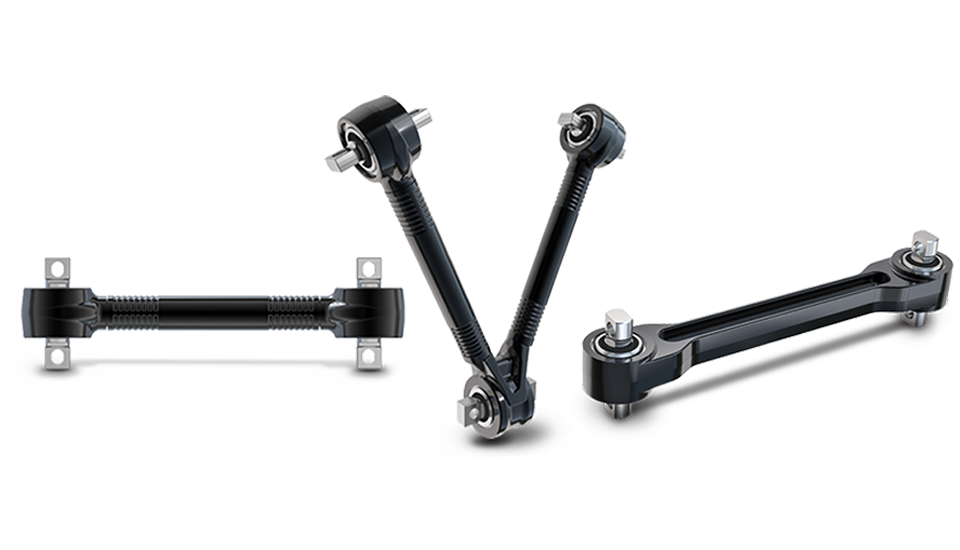

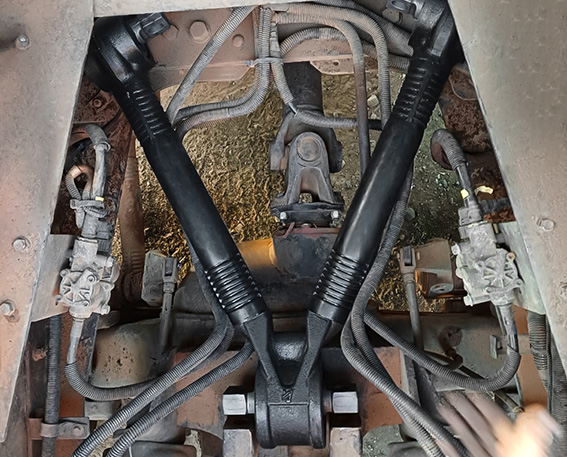

We test, examine and analyse the products to achieve targeted product quality and cost.

To ensure the longer service life of our components, Accurub conduct different stringent tests at each stage of development process. We rely on our expertise, experience and updated testing equipment to ensure the top quality standards of our components.

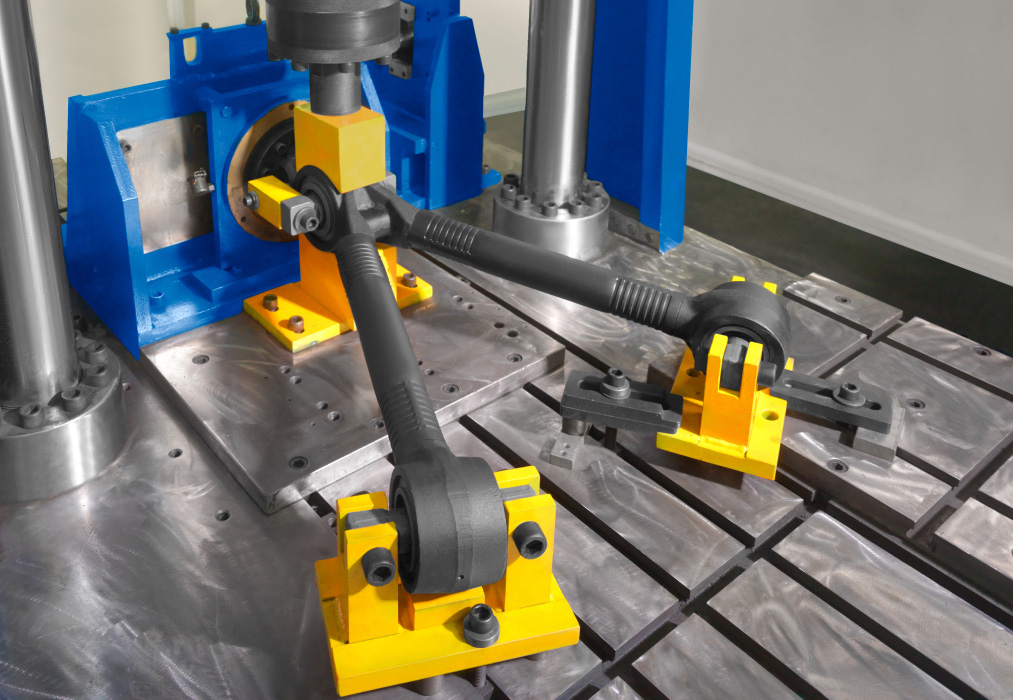

4 - Axis Endurance Tests

3 - Axis Static Test

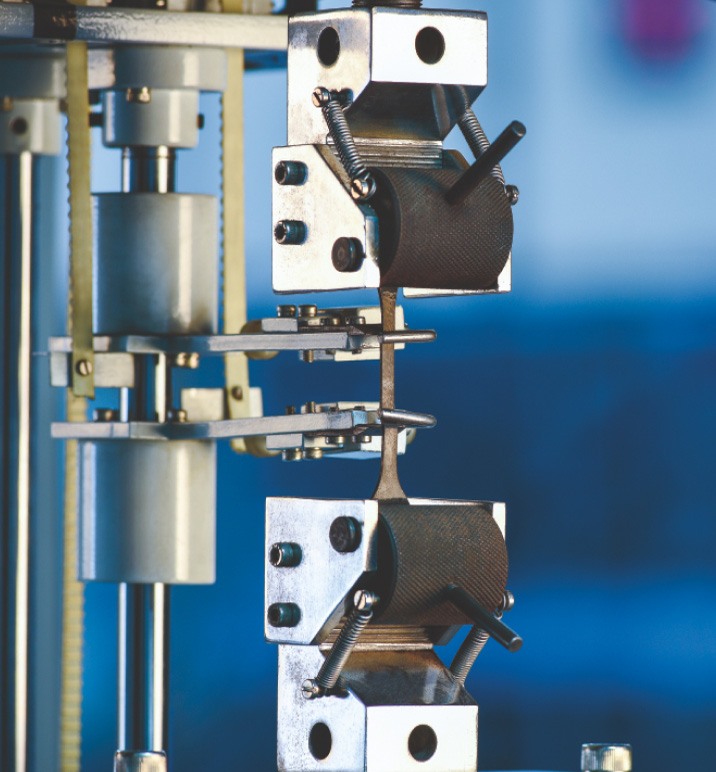

Single Axis Dynamic Test

Ozone Simulation Tests

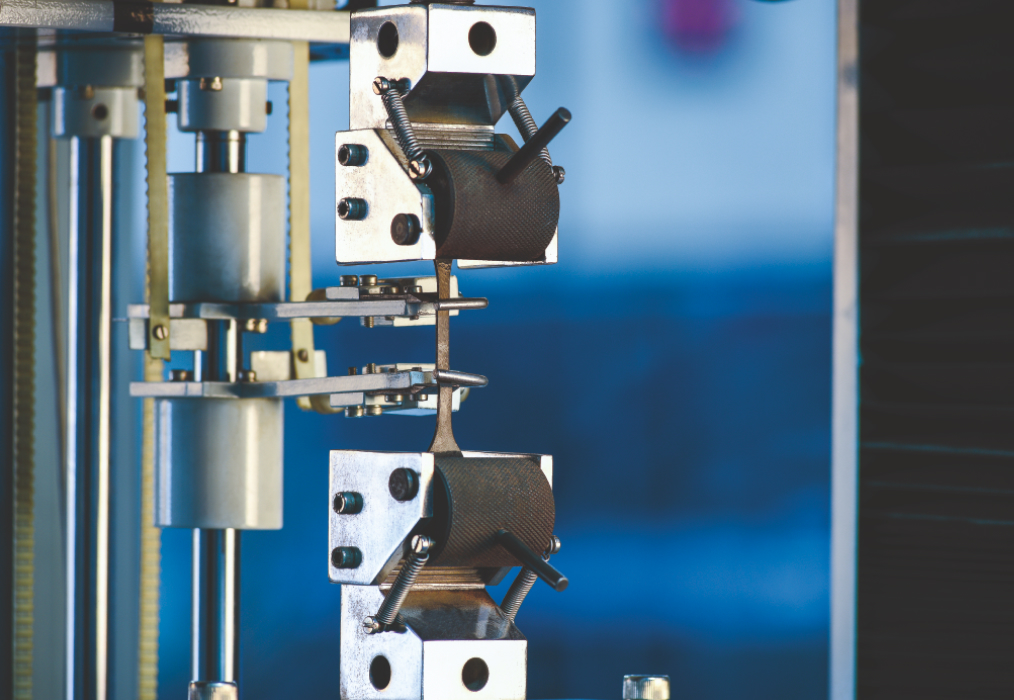

Universal Testing Machines

4 - Axis Endurance Tests

Top notch testing mechanism to validate the Fatigue Life of Product.

Top notch testing mechanism to validate the Fatigue Life of Product.3 - Axis Static Test

Real-time method to evaluate the stiffness of a component under different varying loads and frequencies.

Real-time method to evaluate the stiffness of a component under different varying loads and frequencies.Single Axis Dynamic Test

Advanced methods to check the dynamic stiffness up to 1000 Hz frequency.

Advanced methods to check the dynamic stiffness up to 1000 Hz frequency.Ozone Simulation Tests

Assessing polymer environmental resistance in real time under extreme weather conditions.

Universal Testing Machines

Conducted to assess the tensile and compressive strength of rubber formulations and products.

Conducted to assess the tensile and compressive strength of rubber formulations and products.03

Validate

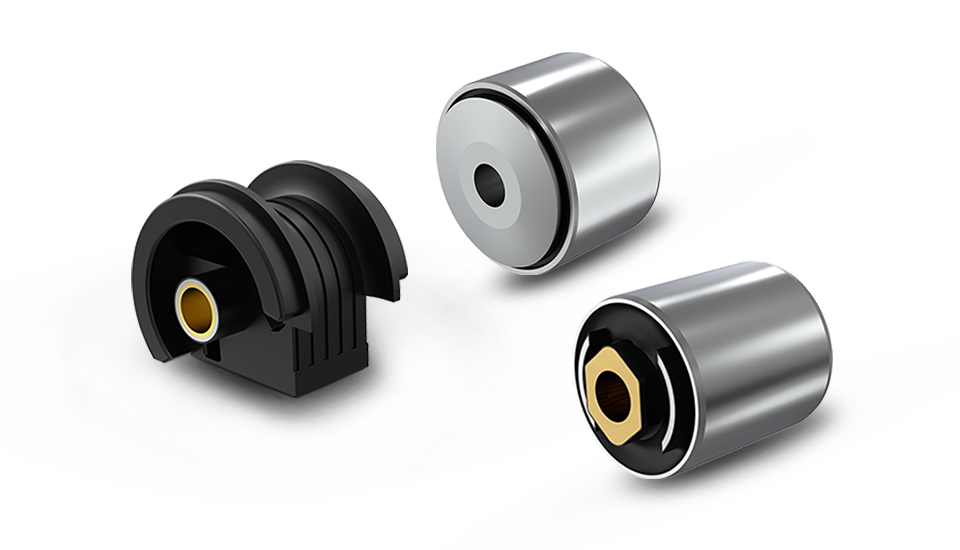

Component prototypes and tested products go under the validation process cycle at the validation unit at Accurub.

Our technicians have developed validation process cycle checks if the component does exactly what it was designed to do in a safe, secure, and reliable manner. At validation stage we not only ensures the

quality and reliability of component but a holistic user experience as a whole. Real time environment and on road product test data is further analysed to validate the component or assembly system.

Accurub Tech Centre is well equipped with specialized hardware and software that can create advanced simulation and automation environments, streamline the collection and reuse of data, and share information among large distributed teams.

Know the latest Accurub News

Attending every important trade fair around the world with a strong presence.